PRODUCTS

- Distribution Transformer

- Resin Casting Dry Type Power Transformer

- Whole-sealed Type Distribution Power Transformer

- Electrical Power Fitting

- Power Transmission and Distribution Fittings

- Power Line Fittings

- Power Line Helical Fittings

- High Voltage Outdoor Electrical Equipment

- Copper and Aluminum Contact Arms

- Lightening Protection Grounding Clamps

- Electric Wire & Cable and Accessories

- Rubber Sheathed Cable for General Purposes

- Rubber Insulated Cables Used in Open Countr

- Flame-retardant Rubber Sheathed Cables for Mining Purposes

- PVC Insulated Cable for House Wiring

- XLPE Insulated Power Cable

- PVC Insulated Power Cable

- Low-smoke Halogen-free Flame-retardant and Fire-resistant Cables

- Control Cables

- Overhead Conductors and Cables

- Aluminum wire and ACSR

- Special Cables

- Elevator Cable

HOTLINE

0577-57157777

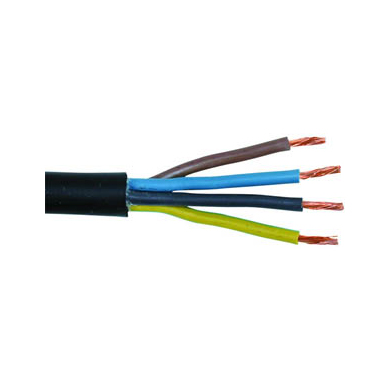

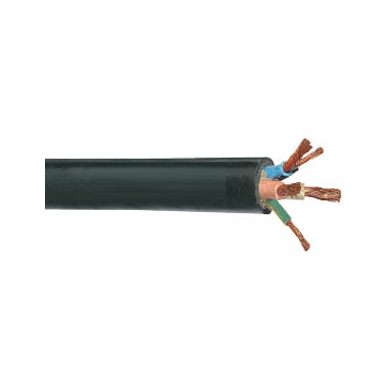

Rubber Insulated Cables Used in Open Countr

Rubber InsuIated Power Cable Used in Open Country

- Share:

1. Standard

Q/YL11-2008

2. Application

This product is used as power connecting wire of portable electrical equipment with a AC rated voltage of 500V or DC rated voltage of 1000V in open country.

3. Guide to Use

The ambient temperature is -45 to +50℃, and the max. conductor temperature in normal use is 65 ℃.

| Code |

No. of cores * Sectional Are (mm2) |

Conductor strands/dia. (mm) |

Insulation Thickness (mm) |

Sheath Thickness (mm) |

Overall Dia. (mm) |

Max. conductor DC Resistanct at 20℃ (Ω/km) |

| YHD | 2 1.0 | 32/0.20 | 0.9 | 1.4 | 10.6 | 20.0 |

| 2*1.5 | 30/0.25 | 0.9 | 1.4 | 11.2 | 13.7 | |

| 2*2.5 | 49/0.25 | 0.9 | 1.4 | 12.9 | 8.21 | |

| 2*4 | 56/0.30 | 0.9 | 1.4 | 14.1 | 5.09 | |

| 2*6 | 84/0.30 | 0.9 | 2.3 | 17.6 | 3.39 | |

| 2*10 | 84/0.40 | 1.1 | 2.8 | 22.2 | 1.95 | |

| 2*16 | 126/0.40 | 1.1 | 3.3 | 26.4 | 1.24 | |

| 2*25 | 196/0.40 | 1.3 | 4.3 | 32.2 | 0.795 | |

| 3*10 | 32/0.20 | 0.9 | 1.4 | 11.1 | 20.0 | |

| 3*1.5 | 30/0.25 | 0.9 | 1.4 | 11.9 | 13.7 | |

| 3*2.5 | 49/0.25 | 0.9 | 1.4 | 13.7 | 8.21 | |

| 3*4 | 56/0.30 | 0.9 | 2.3 | 17.1 | 5.09 | |

| 3*6 | 84/0.30 | 0.9 | 2.3 | 18.6 | 3.39 | |

| 3*10 | 84/0.40 | 1.1 | 3.3 | 24.5 | 1.95 | |

| 3*16 | 126/0.40 | 1.1 | 3.3 | 27.8 | 1.24 | |

| 3*25 | 196/0.40 | 1.3 | 4.3 | 34.0 | 0.795 | |

| 4*1.0 | 32/0.20 | 0.9 | 1.4 | 12.1 | 20.0 | |

| 4*1.5 | 30/0.25 | 0.9 | 1.4 | 13.7 | 13.7 | |

| 4*2.5 | 49/0.25 | 0.9 | 2.3 | 17.1 | 8.21 | |

| 4*4 | 56/0.30 | 0.9 | 2.3 | 18.5 | 5.09 | |

| 4*6 | 84/0.30 | 0.9 | 2.8 | 21.2 | 3.39 | |

| 4*10 | 84/0.40 | 1.1 | 3.3 | 26.5 | 1.95 | |

| 4*16 | 126/0.40 | 1.1 | 4.3 | 32.5 | 1.24 | |

| 4*25 | 196/0.40 | 1.3 | 4.3 | 36.9 | 0.795 | |

| 5*1.0 | 32/0.20 | 0.9 | 1.4 | 13.8 | 20.0 | |

| 5*1.5 | 30/0.25 | 0.9 | 2.3 | 16.8 | 13.7 | |

| 5*2.5 | 49/0.25 | 0.9 | 2.8 | 20.1 | 8.21 | |

| 5*4 | 56/0.30 | 0.9 | 3.3 | 21.8 | 5.09 | |

| 5*6 | 84/0.30 | 0.9 | 3.3 | 24.8 | 3.39 | |

| 7*1.0 | 32/0.20 | 0.9 | 2.3 | 17.1 | 20.0 | |

| 7*10.5 | 30/0.25 | 0.9 | 18.0 | 13.7 |

5. Specification

1) The cores of finished cable shall withstand a 50HZ AC voltage test of 1000V for 5 minutes.

2) This conductor resistance of the finished cable shall meet the requirements listed in technical particulars.

3) The resistance between insulations of finished cable shall be no less than 500MΩ·kM when transferred at a temperature of 20℃.