PRODUCTS

- Distribution Transformer

- Resin Casting Dry Type Power Transformer

- Whole-sealed Type Distribution Power Transformer

- Electrical Power Fitting

- Power Transmission and Distribution Fittings

- Power Line Fittings

- Power Line Helical Fittings

- High Voltage Outdoor Electrical Equipment

- Copper and Aluminum Contact Arms

- Lightening Protection Grounding Clamps

- Electric Wire & Cable and Accessories

- Rubber Sheathed Cable for General Purposes

- Rubber Insulated Cables Used in Open Countr

- Flame-retardant Rubber Sheathed Cables for Mining Purposes

- PVC Insulated Cable for House Wiring

- XLPE Insulated Power Cable

- PVC Insulated Power Cable

- Low-smoke Halogen-free Flame-retardant and Fire-resistant Cables

- Control Cables

- Overhead Conductors and Cables

- Aluminum wire and ACSR

- Special Cables

- Elevator Cable

HOTLINE

0577-57157777

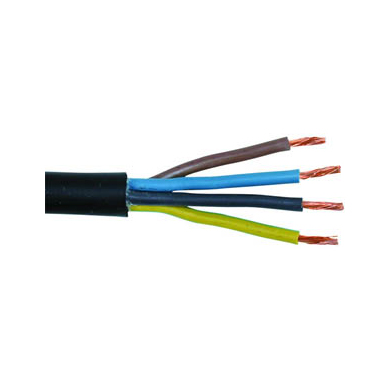

Rubber Insulated Cables Used in Open Countr

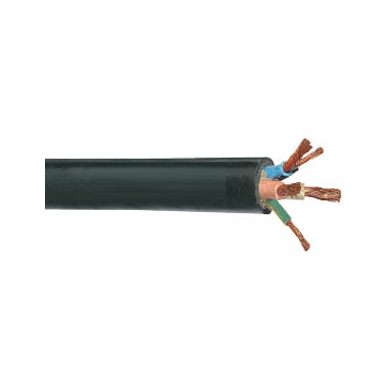

Rubber Insulated Screened Cable Used in Open Country

- Share:

1. Standard

Q/YL12-2008

This product is used for AC rated voltage of 250V and below in open country.

3. Guide to Use

5. Specification

1) A 50HZ AC voltage test of 1000V shall be applied between the cores of finished cable and the cable screen for 5 minutes, and no breakdown shall occur.

2) The conductor DC resistance at 20℃ shall be no more than 19.1Ω/km.

3) The insulation resistance between the core of finshed cable and cable screen at 20℃ shall be no less than 25MΩ·kM.

The ambient temperature is between -45 ~ +50℃, and the max. conductor temperature in normal use is 65℃.

| Code |

No. of Cores * Sectional Area (mm2) |

Conductor Strands/Dia. (mm) |

Overall Dia. (mm) |

Approx. Weight (kg/km) |

| WYHDP | 4*1 | 19/0.26 | 14.5 | 314 |

| 5*1 | 19/0.26 | 16.7 | 400 | |

| 7*1 | 19/0.26 | 17.9 | 484 | |

| 8*1 | 19/0.26 | 19.1 | 538 | |

| 10*1 | 19/0.26 | 22.0 | 660 | |

| 12*1 | 19/0.26 | 22.6 | 739 | |

| 14*1 | 19/0.26 | 23.7 | 815 | |

| 16*1 | 19/0.26 | 24.9 | 904 | |

| 19*1 | 19/0.26 | 27.1 | 1080 | |

| 24*1 | 19/0.26 | 31.2 | 1330 | |

| 27*1 | 19/0.26 | 31.8 | 1440 | |

| 30*1 | 19/0.26 | 32.9 | 1520 | |

| 33*1 | 19/0.26 | 34.1 | 1690 | |

| 37*1 | 19/0.26 | 35.3 | 1840 | |

| 44*1 | 19/0.26 | 39.4 | 2150 | |

| 48*1 | 19/0.26 | 40.0 | 2290 |

5. Specification

1) A 50HZ AC voltage test of 1000V shall be applied between the cores of finished cable and the cable screen for 5 minutes, and no breakdown shall occur.

2) The conductor DC resistance at 20℃ shall be no more than 19.1Ω/km.

3) The insulation resistance between the core of finshed cable and cable screen at 20℃ shall be no less than 25MΩ·kM.